3 Ply, 5 Ply, 7 Ply Corrugated Boxes: Which One Is The Best?

In today’s fast-paced e-commerce and shipping world, good packaging is more important than ever. Corrugated boxes are a key part of this, offering different levels of strength and protection. Understanding the differences between 3 ply, 5 ply, and 7 ply corrugated boxes can help businesses choose the best option for their needs.

In this article, we provide detailed information on the technical details, practical uses, and benefits of 3 ply, 5 ply, and 7 ply corrugated boxes, helping businesses optimize their packaging strategies.

What is Ply in Corrugated Boxes?

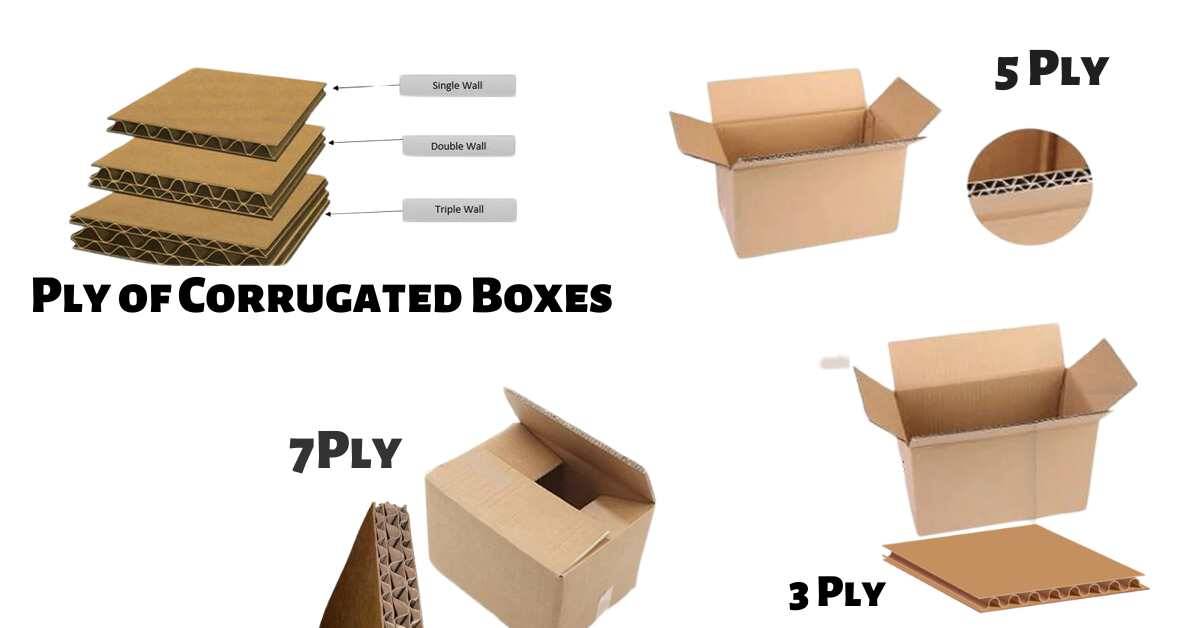

Corrugated boxes are fundamental in the packaging industry, offering varying levels of protection based on their construction. The term “ply” refers to the number of layers of paperboard used in these boxes, determining their strength and durability.

Why Choose Different Types of Corrugated Boxes?

Here are the details and information on the differences and types of 3 ply, 5 ply, and 7 ply corrugated boxes:

What Is a 3 Ply Corrugated Box and When Should You Use It?

A 3 ply corrugated box consists of one layer of fluted paper sandwiched between two layers of linerboard. This construction creates a lightweight yet moderately sturdy box. The fluted layer acts as a cushion, protecting contents from minor impacts.

- Technical: One layer of fluted paper between two layers of liner board.

- Informative: Suitable for lighter products that don’t require heavy-duty protection.

- Usage: Commonly used for packaging small consumer goods, light electronics, and inner packaging within larger boxes. For instance, retailers use 3 ply boxes for shipping clothing items or small accessories. These boxes are also popular in the food industry for bakery products and fresh produce, ensuring protection while minimizing shipping costs.

What Is a 5 Ply Corrugated Box and When Is It the Best Choice?

A 5 ply corrugated box features two layers of fluted paper, each separated by linerboard, providing enhanced strength and rigidity. This additional layer increases the box’s ability to withstand compression and puncture.

- Technical: Two layers of fluted paper between three layers of liner board.

- Informative: Balances cost and durability, making it suitable for medium-weight goods.

- Usage: Often used for shipping electronics, household items, and other products needing more protection than a 3 ply box can offer. Companies use 5 ply boxes to transport kitchen appliances, ensuring they arrive intact. They are also used in the automotive industry for shipping car parts and accessories.

What Is a 7 Ply Corrugated Box and Why Is It Essential for Heavy-Duty Needs?

A 7 ply corrugated box includes three layers of fluted paper separated by four layers of liner board, offering maximum strength for heavy-duty needs. This robust construction provides exceptional resistance to compression and impacts.

- Technical: Three layers of fluted paper between four layers of linerboard.

- Informative: Designed for the heaviest and most fragile items, requiring superior protection during shipping and handling.

- Usage: Typical uses include packaging heavy machinery parts, large appliances, and bulk industrial products. Manufacturers of heavy equipment or furniture use 7 ply boxes to ensure product safety during transport. They are also ideal for shipping large quantities of goods, such as bulk food items or beverages.

More Blogs:

- Cardboard vs. Corrugated: The Box Battle

- The Ultimate Guide to Corrugated Boxes: Types, Uses, and Benefits

Comparison Table of 3 Ply, 5 Ply, and 7 Ply Corrugated Boxes

Here’s a detailed comparison of 3 ply, 5 ply, and 7 ply corrugated boxes to help you understand their differences and choose the best option for your packaging needs.

Advantages of Each Type of Corrugated Box

To help you choose the right packaging solution, here are the benefits and advantages of 3 ply, 5 ply, and 7 ply corrugated boxes explained in simple terms.

Why Choose 3 Ply Corrugated Boxes?

- Lightweight and easy to handle.

- Cost-effective for less demanding applications.

- Ideal for inner packaging and light products.

Reasons to Choose 5 Ply Corrugated Boxes

- Balances cost and strength.

- Suitable for a wide range of medium-weight products.

- Commonly used for both export and domestic shipping.

Advantages of 7 Ply Corrugated Boxes

- Provides maximum protection for heavy and fragile items.

- Ensures safety during long-distance and international shipping.

- Preferred for industrial and commercial heavy-duty packaging.

Applications in Different Industries for 3 Ply, 5 Ply, and 7 Ply Corrugated Boxes

Discover how 3 ply, 5 ply, and 7 ply corrugated boxes are used across various industries to meet specific packaging needs and ensure product safety.

- Retail: 3 ply boxes are ideal for packaging retail goods like apparel and accessories.

- Electronics: 5 ply boxes protect electronic devices from shocks and impacts during shipping.

- Food and Beverage: 5 ply and 7 ply boxes ensure the safe transportation of bulk food items and beverages.

- Heavy Machinery: 7 ply boxes provide the necessary durability for shipping heavy machinery and parts.

Frequently Asked Questions About Corrugated Boxes

Q. What does “ply” mean in corrugated boxes?

A. “Ply” refers to the number of layers of paperboard in the construction of a corrugated box. More layers mean a stronger box.

Q. How does the ply count affect the strength of a corrugated box?

A. Higher ply counts generally result in stronger and more durable boxes, capable of withstanding heavier loads and providing better protection.

Q. What are the cost implications of using higher-ply corrugated boxes?

A. Higher ply boxes are more expensive due to the additional materials and manufacturing complexity, but the cost is justified for items needing extra protection.

Q. Can the ply count be customized for specific needs?

A. Yes, the ply count can be customized based on application requirements. Consult a packaging expert to determine the most appropriate ply count.

Q. What is the difference between 5 ply and 7 ply corrugated boxes?

A. 5 ply corrugated boxes have two layers of fluted paper separated by three layers of linerboard, offering strong protection for medium-weight goods. In contrast, 7 ply corrugated boxes have three layers of fluted paper separated by four layers of linerboard, providing maximum strength for heavy-duty items.

Q. Is 3 ply or 5 ply better?

A. 3 ply boxes are better for lightweight items that don’t require heavy-duty protection, while 5 ply boxes offer greater strength and are better suited for medium-weight goods. The choice depends on the specific packaging needs.

Q. Is 7 ply better than 5 ply?

A. Yes, 7 ply boxes are generally stronger and more durable than 5 ply boxes. They provide maximum protection for heavy and fragile items, making them ideal for industrial and heavy-duty packaging needs.

Q. How thick is a 7 ply corrugated box?

A. The thickness of a 7 ply corrugated box varies, but it typically ranges from 10 to 12 mm, depending on the materials used and the manufacturing process.

Q. What is the GSM of a 3 ply corrugated box?

A. The GSM (grams per square meter) of a 3 ply corrugated box typically ranges from 150 to 180 GSM for each layer, but it can vary based on specific material and strength requirements.

Conclusion

For businesses looking to enhance their packaging solutions, understanding the differences between 3 ply, 5 ply, and 7 ply corrugated boxes is crucial. Whether you need lightweight packaging for retail goods or heavy-duty protection for industrial products, choosing the right type of corrugated box can significantly impact product safety and customer satisfaction.

Contact us today at Gurez to explore our range of corrugated boxes and find the perfect packaging solution for your business needs.